|

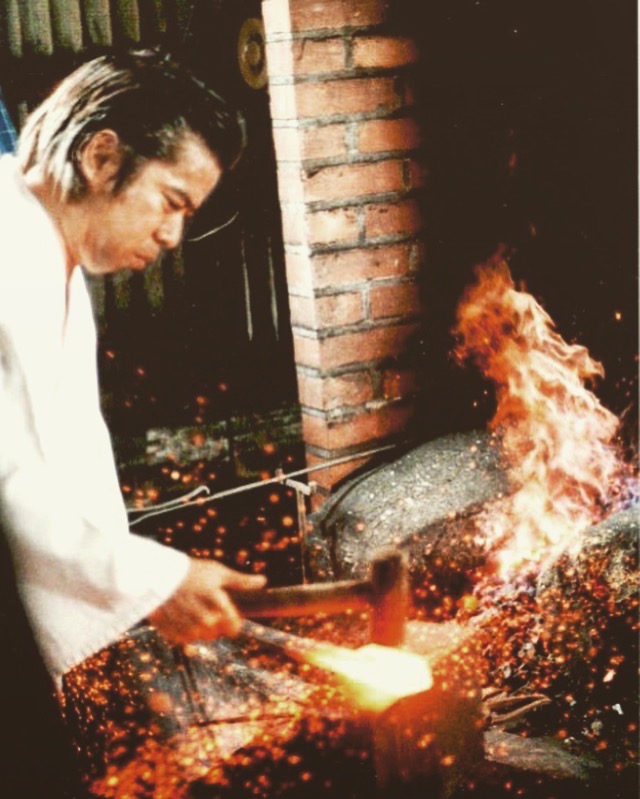

Shosui Takeda: Niimi, Japan Takeda Hamono was founded in 1920 and is currently forging out of Niimi-shi, Okayama. Shosui Takeda has become a gold standard in hand-forging blades from the highest quality Aogami Super Steel (AS). He succeeded his father in 1985 as 3rd generation of the forge. Takeda’s knives are made alongside his small team of master-smiths, and each blade has amazing edge-retention and sharpen-ability. Each blade is one of a kind, and no two are exactly the same. The knives are beveled 50/50 with a kurouchi finish, octagonal rosewood handles, so they are friendly to either right-handed or left-handed users. They have an HRC 63-64. |

|

Konosuke: Sakai, Japan The Kawamura family has been producing knives as Kaneshige Cutlery since 1932. Konosuke's mantra is to continually innovate, to always strive to elevate their knowledge and consistently exceed their benchmarks of excellence. With extremely high standards in fit and finish they have a fierce following all over the world. Their creativity and dedication to their craft is changing the canvas of Japanese knife design. |

|

Teruyasu Fujiwara: Tokyo, Japan Established in 1870, Teruyasu Fujiwara the first began his career as a master blacksmith, forging farm tools. When his son Fujiwara the second was of age, he was apprenticed to the famous Tokyo swordsmith Masahide Suishinshi. After years of training, he returned to his father’s shop and became a successful master bladesmith. The family continued this tradition until sword making was restricted after WWII. By the end of the 1960s, the Fujiwara family began making kitchen knives, determined to make knives that would make a swordsmith's family proud. It took all of the knowledge gained by the family from more than 100 years of forging swords to successfully produce their current line of professional cutlery. Since the late 1990s, fourth-generation Fujiwara has continued over 130 years of family tradition. Being san-mai clad blades, you get all the performance of hi-carbon steel edge (razor edge performance and sharpening ease) without the overall maintenance issues (rust, oxidation). His blades have unparalleled edge retention, are made of #1 Shirogami white carbon clad with stainless steel, and has an HRC of 64-65.

|

|

Takamura: Echizen, Japan Handmade by the Takamura clan of Echizen, the three brothers work under the watchful eye of their master blacksmith father to create true handforged knives of the Echizen region. This region has a rich history of blade production, as they have been hand forged here since the Muromachi period (1392-1573). Today, the forge is run by 3rd generation blacksmith Terukazu Takamura who inherited the shop from his father Toshiyuki Takamura-san.Takamura knives are made in their workshop in Fukui prefecture, from forging to the final sharpening and polishing of the blade, and their knives are used by chefs from elite kitchens around the world. Twenty years ago Takamura Hamono pioneered the use of R2 powdered stainless steel in kitchen knives. Today they are considered the leading powder steel knifemaker in Japan. This steel is so hard, it was originally used to build the shinkansen railways. These knives are surgically sharp and have incredible edge-retention.

|

|

Kanehiro: Echizen, Japan Kanehiro was founded in 1953 by Kintaro Kato (1914) who began forging kitchen cutlery in 1928. The company has built up a vast array of experience and knowledge of knife making and is one of the most respected forges in Echizen. Hiroshi Kato received the certification of the traditional craftsmen of Japan in 2008, and now runs this small forge from the Takefu Knife Village in Echizen. He is one of the founders of the village established over 20 years ago as a co-op for education and distribution for cutlery of the prominent bladesmiths of Echizen. |

|

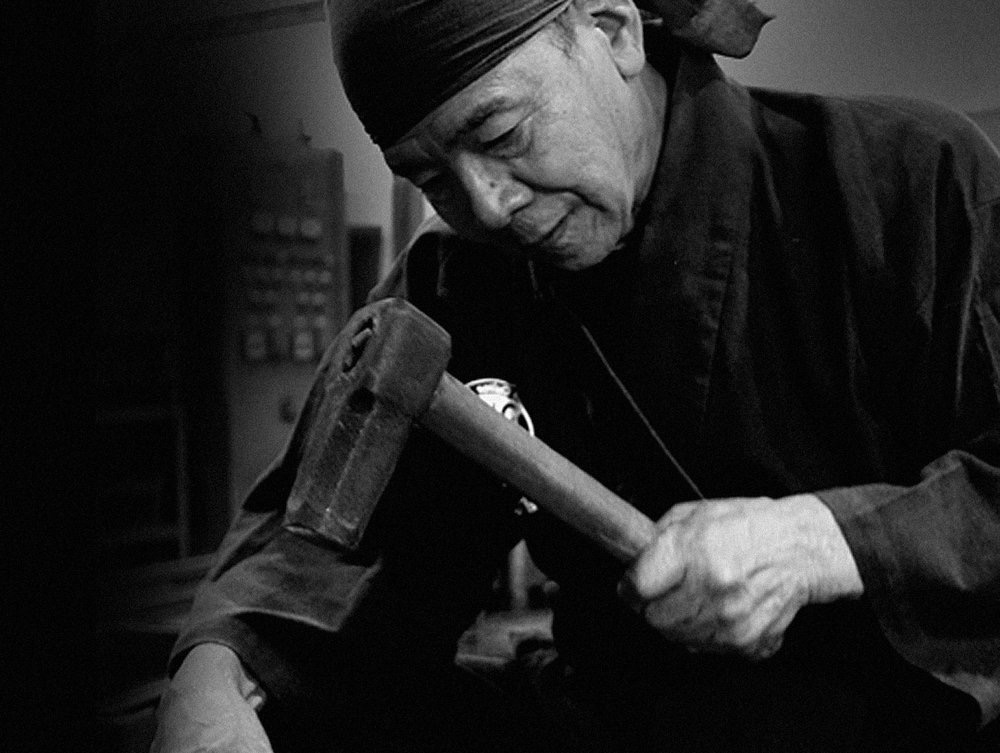

Sukenari: Toyama, Japan Sukenari was founded in the year 1933 by Master Hanyaki Toukichi after working for Japanese famous sushi knife maker Masamoto and mastering the traditional way of forging and knife making process. Located in Toyama prefecture, in the center of Japan and Sukenari knives are popular and well known among professional Japanese chefs in the area. They make the knives and sell them directly to Japanese chefs (by visiting and showing them the products each time.) This was the first and original way of selling in any industry, yet, we are impressed to find that the craftsmen and forge-smiths are also in charge of sales. They are one of the last charcoal forges left in Japan. Sukenari is renowned worldwide for their exceptional work making Honyaki Shirogami#1 knives and handmade ZDP-189 blades. Only a few blacksmiths in Japan are capable of forging pure 100% carbon steel Honyaki knives and even fewer make handmade ZDP-189 knives, the skills and expertise required are immense. Sukenari high end quality knives have attracted quite a following in central Japan, and in recent years, in the rest of the world as well. Some consider their knives to be the best in the world.

|

|

Takeo Murata: Kochi, Japan Takeo Murata is the premier bladesmith of Shikoku Island and his knives are regarded as some of the best in Japan. He specializes in aogami #1 steel, a high density blue carbon with great edge retention. He knives are know for good balance and sharpness, and sharpenability to a mirror finish. The blades have a traditional kurochi finish (blacksmith's finish) which is the natural result of burning of the carbon while it's in the coal fire. This finish is sometimes polished off, but he has decided to leave it on the blade to reduce oxidation. It fades beautifully over time with a desirable patina.

|

|

Masakage: Hiroshima, Japan Since 2007, Masakage has offered a few lines of the finest Japanese cutlery made by a small team of master blacksmiths; truly superior hand-forged excellence. The forge is lead by 4th generation master-smiths Hiroshi Katoand Katsushige Anryu. Both men helped to establish the Takefu Knife Village in Echizen almost 25 years ago. All Masakage knives are hand sharpened by Takayuki Shibata-san, one of the best professional master knife sharpeners in Japan. All blades can be used easily by the right or left-handed, only using oval and octagonal handles. The handles are set back a bit further from the handle to maximize comfortability and knuckle clearance. |

|

Murray Carter: Hillsboro, Oregon 17th generation Yoshimoto master bladesmith Murray Carter has an amazing story. At the age of 18, Murray began apprenticing under Sakemoto-san in the tradition of Yoshimoto bladesmithing. After many years of apprenticing in Kumamoto, Japan he was asked by the family to take the 17th position in the lineage of the tradition. He is the only American to ever be given such a distinction. In 2001 he was awarded Mastersmith status by the American Bladesmith Society and continues forging the highest quality cutlery with his team out of his shop in Oregon. Traditionally, his knives are forged with Hitachi high carbon steel laminated between SUS410 stainless with an HRC 62-64. |

|

Quintin Middleton: St. Stephens, South Carolina Hailing from Saint Stephen, SC, Quintin is a true artist in every sense. His passion, skill, technique, and craftsmanship come through in every blade he forges. As one of the premier bladesmiths in the southern United States, he has garnered accolades from some of the best chefs in the country for his cutlery’s style and elite performance. He has been hand-crafting knives since 2003 and has had the fortune to be mentored by fellow South Carolina master bladesmith, Jason Knight; among other influences such as Jerry Hucks, Michael Rader, and the legendary Bob Kramer.

|

|

Shi.Han: Santa Fe, New Mexico Sheehan Prull began studying metalwork at age twelve with internationally recognized artist blacksmith, Tom Joyce. By the time he graduated from high school, blacksmithing had become a calling to which he wished to dedicate my life. After studying ornamental ironwork with Joyce and others, he traveled to Japan as a journeyman. While visiting blacksmiths throughout the country he was fortunate to meet one of Japan's master knife-makers, Hiroshi Ashi, who kindly hosted him for the next two years. Thanks to His patronage, Sheehan studied and practiced with many artisans in the city of Sakai, renown for its cutlery and bladesmithing. He returned to Santa Fe in 2009 determined to build my own shop based on the techniques and philosophy that he learned from the craftsman of Japan. The name Shi.han, derives from re-translating the Japanese form of my name 獅絆 back into English, reflecting his journey from the US to Japan and back again. |

|

Moritaka Hamono: Kumamoto, Japan Moritaka Hamono has been producing swords for over 700 years. Founded in 1293 during the Kamakura period in Fukuoka, then moved to Kumamoto in 1632. The Moritaka family gained high praise and esteem by forging swords for the Buddhist priests at Mt. Homan and the Buddhist armies of the Daimyo era, and even the Daimyo himself. Five generations ago, master swordsmith Chuzaemon Moritaka decided to expand production to knives. Since then, the Moritaka family have continued to handcraft knives and swords that samurai would be proud of. The outstanding quality of their blades is established by using a combination of a steel core and iron cladding. The steel core gives their knives razor sharp edges, while the iron cladding ensures durability that surpasses any mass production knives. |

|

Sakai Takayuki: Sakai, Osaka, Japan The Sakai region of Japan has one of the longest and storied traditions of knife and sword making in all of Japan. 600 years of blademaking knowledge go into the Blades that come from this region. While the number of craftsmen with excellent skills decreases every year, the knives of Sakai Takayuki have maintained an excellent reputation for superb craftsmanship and clean cutting. For the last 70 years, the Aoki Hamono Seisakusho Co. has helped continue this ancient tradition while incorporating more modern and advanced technologies. The work of master bladesmiths such as Suogo Yamatsuka and Ituo Doi as well as master sharpeners such as Hirotsugu Tosa have allowed Sakai Takayuki to produce some of the finest cutlery from Sakai.

|

|

Jared Thatcher: BootHill Blades; Lafayette, KY Jared began making knives in 2013 after using a sub-par knife to skin a deer. The thought of crafting tools that could be used over and over again from recycled materials bagan to consume his thoughts and thus, BootHill Blades was born. What began as an outlet to relieve stress from a career in finance quickly blossomed into passion; fueled by good food & better friendships. With the guidance of Luke Snyder, Cris Anderson, and Tom McLean; Jared began crafting his own custom kitchen tools. Him and his wife Kylee continue this tradition through Jared’s knives and Kylee’s woodwork (BootHill Kitchen) at their home & farm in Kentucky.

|