STEEL INFORMATION AND TERMINOLOGY

There are many different types of steels that are used for blade making. Each type of steel has its own unique characteristics and the same steel in different craftsman’s hands can yield many different results; much like chefs cooking with similar ingredients.

There are three general types of steel that are common in Japanese Cutlery.

- CARBON

- STAINLESS

- CLAD - Carbon & Stainless

Each type of steel has many varieties depending on the blade smith’s preferences and the customer’s performance desires

CARBON STEELS

Named for the colored paper attached to the steel at the HITACHI factory in Japan...Not Rust Resistant!!! Much like a cast iron pan; these blades must be kept CLEAN & DRY when not in use. A light layer of blade (Tsubaki) oil will help protect the blade from rust, especially in humid climates. Carbon Steel is easy to sharpen and forms a terrific edge. If properly cared for, carbon steel will form a beautiful patina over time but if neglected, they can rust.

White Paper (Shirogami) Steels

This is a very pure form of carbon steel that oxidizes faster that blue steel but is easier to sharpen and creates a terrific edge.

There are three types or grades of Shirogami steel:

- Shirogami #1 - The hardest white paper steel. It will stay sharp the longest but can be a tad brittle under aggressive use.

- Shirogami #2 - Most commonly used type of white steel. Good edge retention and very easy to sharpen.

- Shirogami #3 - The most durable of the three types; but it will dull more quickly.

Blue Paper (Aogami) Steels

Blue steel is essentially white paper steel in which Chromium (Cr) and Tungsten (W) have been added. These alloys allow for blue steel to be harder than white steel. Blue steel is also reactive, but less than Shirogami. Designed for knives and tools; this steel has supreme edge retention while remaining easy to sharpen.

Blue paper steel also has three grades:

- Aogami Super - Vanadium (V) is added to make this steel super strong and hard. Top notch edge retention for carbon steel with great wear resistance.

- Aogami #1 - Less common than #2 and Super, but forms a terrific edge that stays sharper longer than #2.

- Aogami #2 - The most durable of the blue steels. A tough steel that sharpens easily.

Yellow Paper (Kigami) Steels

Much less common in high-grade Cutlery but it is often used for tool making and agricultural products like sickles, hatchets, and axes.

STAINLESS STEELS

These steels have a much lower carbon content and contain at least 10.5% Chromium (Cr). Although generally a little harder to sharpen than high carbon knives, stainless steel knives are much more rust resistant and they are very easy to maintain. They contain many more alloys such as Molybdenum (Mo), Vanadium (V), Nickel (Ni), and Cobalt (Co) to form a wide variety of steels suitable for both beginners and professionals.

Molybdenum Vanadium Steel

A common type of stainless steel that is of good quality. Very durable steel that is great for beginners and people who are rough with their knives. Easy to re-sharpen but will need to be re-sharpened more quickly than other varieties.

VG-10 Steel

The most common type of stainless steel found in Japanese Cutlery due to its good edge retention and moderate ease of sharpening. Cobalt (Co) adds toughness and durability. A high Vanadium (V) content gives this steel high rust resistance. Often used in Damascus and Migaki style blades.

AUS-8 & AUS-10 Steel

Less Chromium (Cr) makes these steels less rust resistant than VG-10 but Nickel (Ni) adds to its toughness and durability. A great middle ground between edge formation and edge retention.

High Speed Powdered Steels - R2, SG2, SRS-15

Called “powdered” steel because of the very fine grain structure of this steel. The fine grain structure allows for excellent edge formation. Also used for the rails of the high speed trains as well as drill bits; these are extremely hard steels with the longest edge retention of any stainless steel. Although harder to sharpen, the edge durability of these steels make them ideal for professionals who are demanding of their cutlery.

Gin-san Steel - Gingami #3

This is a special HITACHI steel that functions similar to a semi-stainless steel. It has more rust resistance than high carbon steels, but less than most stainless steels. this steel forms a terrific edge with the durability of a stainless steel but with the ease of sharpening that is similar to harder high-carbon steels.

CLAD STEEL

These are blades which contain both high carbon and stainless steels. These blades typically contain a core of Shirogami or Aogami steel with an outer layers of stainless or low-carbon steel. These blades are popular because the user gains the advantage of a carbon edge that is easy to sharpen and forms a terrific edge while not having to worry about oxidation issues across the entire blade. These blades are great for professionals in busy kitchens, or home cooks who want to experiment with carbon steel but are worried about the extra maintenance.

There are two techniques for achieving Clad Steel:

- San-mai - Like a sandwich, a hard carbon core is forge laminated with two thin layers of stainless steel throughout the entirety of the blade

- Warikomi - Like a pita, one piece of stainless steel is heated and folded around the carbon core, leaving the carbon exposed on the edge side but disguised on the spine side.

KNIFE CARE

Wash and dry the blade by hand immediately after use. They are not dishwasher safe.

Use a soft sponge to wash the blade. Avoid abrasive dish scrubbers that may can damage the finish of the blade.

Apply a layer of tsubaki/camilla oil to surface of carbon blades to prevent oxidation and rust.

Do not cut through bones. This can chip the blade.

Never use the knife to cut frozen food.

Never twist, cleave or prise the blade. This can chip the blade.

Always use a wooden or plastic cutting board. Never cut on glass, marble, slate, a plate, china, marble or anything harder than steel. Also avoid bamboo as it is very hard and dulls knives quickly.

Store knives in a way that the blades will not knock into each other (saya covers, magnetic strips).

Use a ceramic honing rod or leather strop for the edge maintenance.

Always sharpen by hand on water stones.

STEEL FINISH

|

KUROUCHI - “Blacksmiths Finish” Kurouchi is the name given to the black, rustic finish found on many Japanese blades. This is actually a byproduct of the forging process that is often polished away. The Blacksmiths would save the time of polishing for their own tools, preferring to leave the black finish on the blade; hence the name. The Kurouchi finish will slowly fade away over time; but while it remains on the blade it will protect the blade from rust and oxidation. Each blade smith has their own unique style and depth of their Kurouchi and even the uniformity of the Kurouchi can vary from blade to blade.

|

|

NASHIJI - “Pear Skin” This aptly named finish comes from the irregular speckling pattern on the side of the blade. It helps to relieve some surface tension while cutting but is mainly aesthetic. Achieved by introducing small metallic fragments to the blade, this finish gives a blade a beautiful, antique look. |

|

TSUCHIME - “Hammered” A popular method during the Edo period, tsuchime refers to blades that have this characteristic dimpled look. Most tsuchime finishes are hand hammered but some can be machine rolled. Sometimes this finish is referred to as Koishi “pebbles”. This finish also helps to relieve some surface tension from starchy or oily foods. |

|

SUMINAGASHI - “Marbled Steel” Also called Damascus steel, this is less of a steel finish and more of a forging technique. The multiple layers of steel are achieved by heating and folding at least two different types of steel together multiple times until a beautiful and artistic mosaic of layered steel is accomplished. This process also helps to strengthen the steel.

|

|

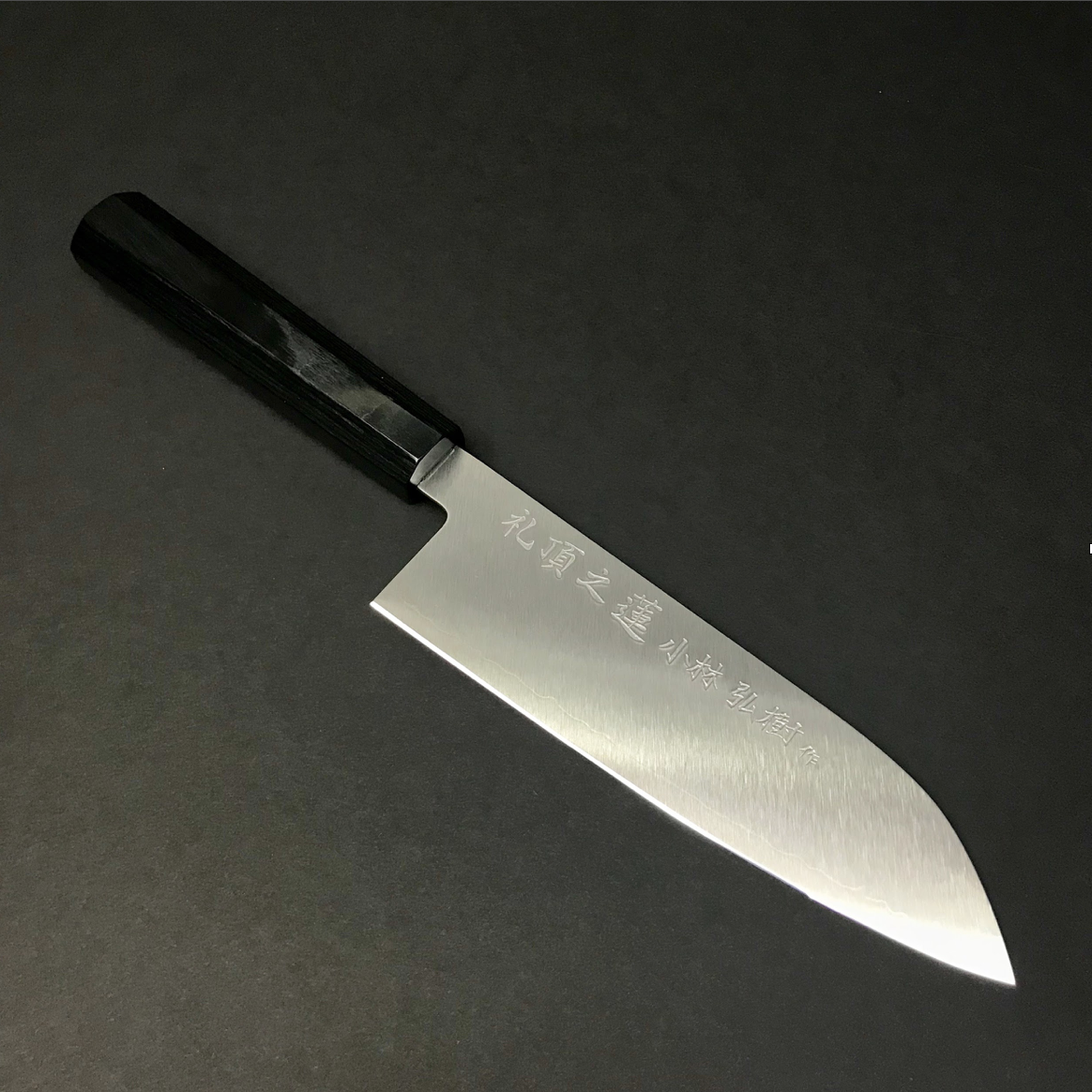

MIGAKI - “Polished Steel” This is when the steel is highly polished. A very simple yet beautiful presentation. Also referred to as Hikari “shiny”, users should be weary of using abrasive sponges or clothes during cleaning. The opposite of a Taganeme finish. |

|

TAGANEME - “Rough Finish” This is a finish achieved when grinding the blade. The sides of the blade are intentionally left with a rough finish which allows for ease of cutting and food separation. This finish makes for a very efficient cutting blade.

|

|

ETCHED - “Acid Treated” This is a process by which a blade’s steel is introduced to Ferric Chloride or some other type of solution high in acidity. This forces a chemical reaction on the blade that can be used to make decorative patterns on steel. Acid etching is also used to bring out the differences in Damascus steel blades.

|